CASE STUDIES

Digitization of Logistics

Digitization, Automation and Optimization of all Logistics processes for a Traditional Company

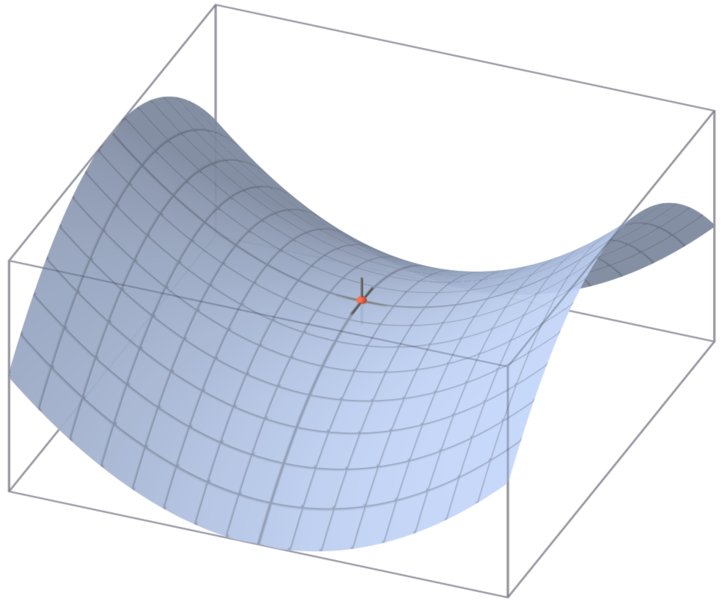

Promotional Sample Optimization

Marketing Sample Optimization for Pharma Companies

Warehouse Space Forecasting

Depot Space Forecasting for a leading postal and courier company in the UK

Logistics Optimization

Integrated Multi-Modal Logistics Optimization for a Metal and Steel Company

![Telecom Field Services [ File # csp4999039, License # 3167457 ]

Licensed through http://www.canstockphoto.com in accordance with the End User License Agreement (http://www.canstockphoto.com/legal.php)

(c) Can Stock Photo Inc. / iqoncept](https://saddlepointtech.com/wp-content/uploads/2019/03/Telecom-Field-Services-200x150.jpg)

![Telecom Field Services [ File # csp4999039, License # 3167457 ]

Licensed through http://www.canstockphoto.com in accordance with the End User License Agreement (http://www.canstockphoto.com/legal.php)

(c) Can Stock Photo Inc. / iqoncept](https://saddlepointtech.com/wp-content/uploads/2019/03/Telecom-Field-Services-200x150.jpg)

Field Service Optimization

Optimizing field services for one of the largest Telecom companies of the world

Digitization of Warehouses

360° view of Warehousing Operations across 3PLs through Digitization and Optimization

Global Optimized Order Fulfillment

Improving Rush Order Planning for Pharma Companies

Dock Scheduling

Dock Scheduling & Loading Optimization for one of the world’s largest Swedish F&B company

Network Re-Designing

Warehouse rationalization and impact assessment post GST across various industries

Replenishment Planning

Optimized Replenishment Planning for UK based manufacturer and retailer

BLOGS

- All

- Planning and Optimization

- Supply Chain Analytics

- Supply Chain Collaboration

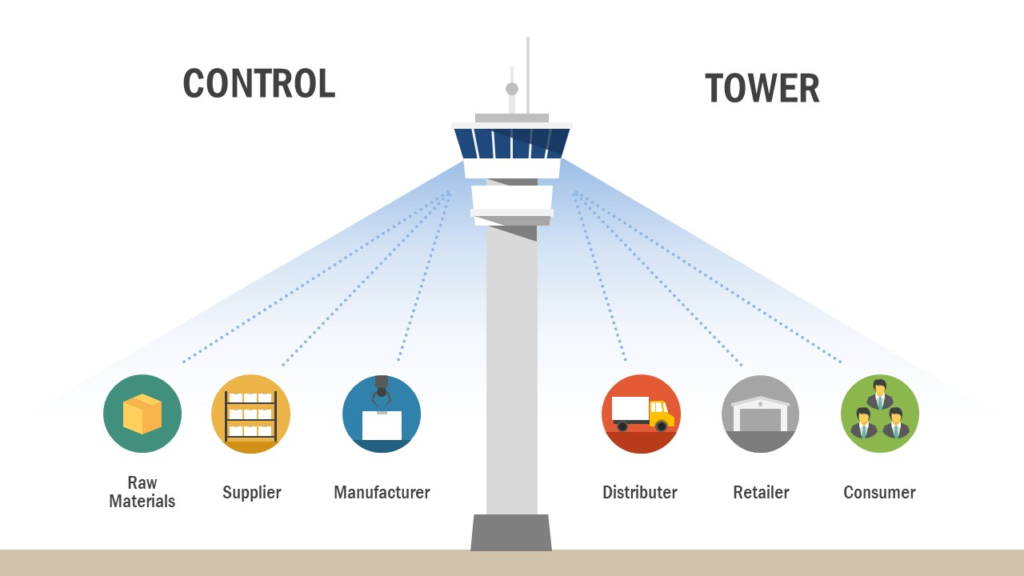

- Supply Chain Digitization

- Supply Chain Visibility