- July 7, 2020

- Posted by: Saddle Point

- Category: Planning and Optimization, Supply Chain Digitization, Supply Chain Visibility

Honest Abe was the Supply Chain head of an F&B company. He was hard working, sincere and capable.

However after putting his best efforts, there were regular complaints of stock-outs from his Distributors. Despite the fact that his warehousing bills from his 3PLs have ballooned in the past couple of years and his inventory write-offs have spiraled out of control, the complaints haven’t abated. Inspite of pushing more material into the supply chain, the stock-outs continued. He often joked that his warehouses were black holes that was gobbling up all his supplies.

Honest Abe desperately needed some eyes in the sky to figure out where his material was going. He came across the concept of 360o view of material for e2e Tracing and Tracking. For this, he needed the support from his warehousing service providers.

Warehousing services were one of the first services to be outsourced to 3PLs. Now, it has become so common that relying on 3PLs for warehousing services has become the defacto standard in the industry.

Warehousing services were one of the first services to be outsourced to 3PLs. Now, it has become so common that relying on 3PLs for warehousing services has become the defacto standard in the industry.

However, 3PLs are a fragmented lot. Most of the 3PLs are strong in a few geographies. This makes the company deal with multiple 3PLs for their warehousing services and since each 3PL use their own homegrown rudimentary warehousing system, a comprehensive and uniform view of material in all warehouses although desired, is left unfulfilled.

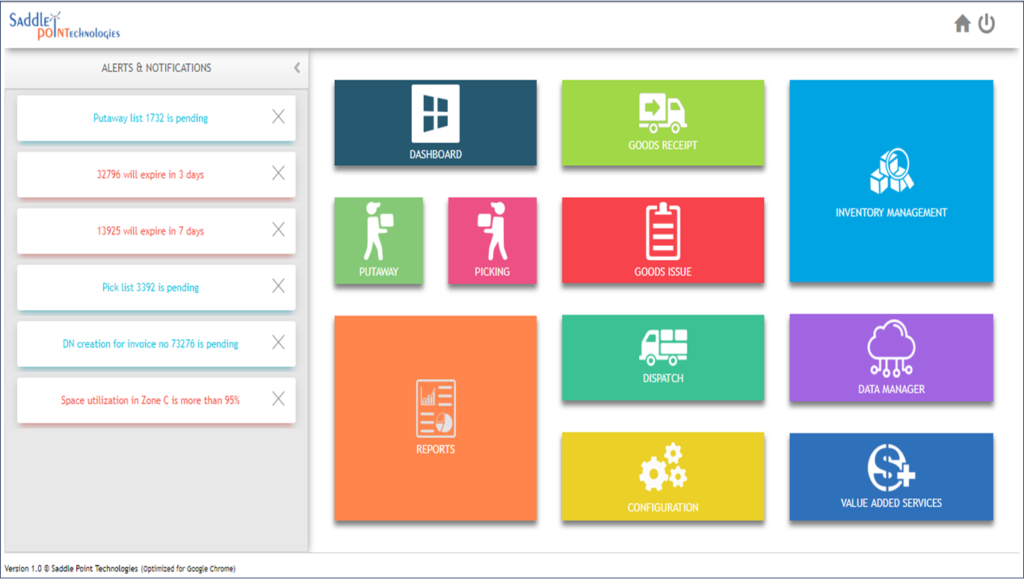

To make this dream a reality, a cloud based, configurable, feature rich, easy to use and affordable WMS solution is what is needed.

By seamlessly integrating the WMS with the ERP system, all 3PL warehouses become seamless extension of the inventory management system of the ERP. This fact alone gives the company the complete control of their stock.

By seamlessly integrating the WMS with the ERP system, all 3PL warehouses become seamless extension of the inventory management system of the ERP. This fact alone gives the company the complete control of their stock.

Visual representation of the entire warehouse layout, single sign-on for all warehouses, configurable alerts for near expiry goods, mobile app based Barcode/QR code/ Text scanning, route optimization for put-away and picking are something that gives the user a much richer experience.

Honest Abe followed the concept to the T and with his flawless execution skills could slowly bring all his 3PLs under the same WMS umbrella. Now he and his team had complete control of the stock and could plan much better for potential shortfalls and inventory write-offs.